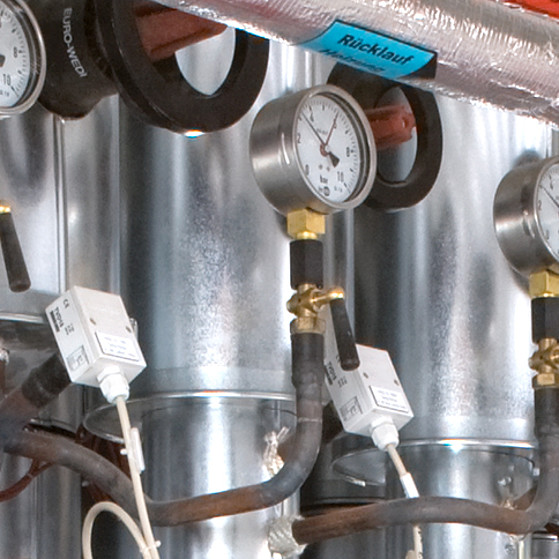

TAD/TLH/TDE Sensors

Reliable and precise recording of temperature and humidity

They provide the reliable base of data for controlling your primary systems: Kieback&Peter’s TAD, TLH and TDE sensors. Made in Germany to the highest quality and sustainability standards, our sensors are extremely precise – over the whole product life cycle, of course. They record actual values like temperature and relative humidity with the lowest tolerances along the entire measurement range. Kieback&Peter has the right model for every application: for example, the sensors work on external walls (TAD), in ventilation and A/C ducts (TLH), and in water pipes in heating systems (TDE).

Fine sensitivity in a hard shell

Any control system depends on valid measurement data: if you don’t measure conditions of your system precisely, you can’t control them optimally. Our sensors are designed for precision and a long service life, so that your automation always runs with precise actual values. The more sensitive, the more fragile – but this does not apply to Kieback&Peter sensors: we have given our sensitive sensors a solid housing. Their robust and functional design promises a long service life and fast installation. The TAD external temperature sensor, for example, meets protection type IP 65. In investing in our sensors, developers are making the right choice. Operators and energy managers will thank them – because they can work with precise measurements in the long term.

3 dudes for all cases: TAD/TLH/TDE

Kieback&Peter TAD temperature sensors record temperatures for heating, ventilation and A/C systems controlled by outside temperature. As it is used outdoors, it is highly protected against the weather and environmental factors. It meets protection class IP 65 – so is completely dust-proof and has protection against spray water from any direction. International Protection (IP) is an international standard, defined by ISO 20653 and DIN EN 60529.

The Kieback&Peter TLH combined temperature and humidity sensor measures two values precisely and reliably. It is used in ducts in ventilation and A/C systems.

The TDE temperature sensor measures the temperature of the heating and cooling medium in pipes in heating, ventilation and A/C systems. Reliable at all times: our sensors are top-quality German products from Kieback&Peter.

RBW/RPW Control Units

Smart and flexible room automation with integrated sensors

Kieback&Peter RBW/RPW room control units are interfaces between humans and building technology. With them, users set room temperature, ventilation, light, blinds and more. The integrated sensors simultaneously record temperature, humidity and presence, and send the values reliably to the room or building automation system. The RBW models can be configured. You can use them to set up individual scenarios, such as “Presentation” for conference rooms: At the touch of a button, the blind closes, the light is dimmed and a screen comes down. The self-learning RPW models have another feature on board: they record the times when a room is occupied and create a user profile on that basis. With this information, they control heating according to need. Of course, Kieback&Peter also has wireless solutions for room automation. They are ideal for cost-effective retrofitting to building stock, as they need neither wiring nor a power supply.

Modernizing buildings cheaply and efficiently

Huge energy-saving potential lies dormant in old buildings – that is true of both residential and non-residential properties. But many developers and planners are scared of the high investment that insulation and other conventional modernization work involves. Kieback&Peter offers smart alternatives here. Our wireless portfolio is especially suitable for cost-effective retrofitting: the installer can fit the parts without much work – no cable slots, no installation in false ceilings. Our award-winning en:key product set is a pioneer of smart heating. The self-learning room control – consisting of RPW and a small actuator – provides average heating energy saving of 20 percent. And with minimum installation work. Because en:key communicates via the EnOcean wireless standard and is energy-independent, it does not need a single wire.

5 good reasons for RBW/RBW Control Units

E.g. hotels: Well-controlled hotel rooms linked to booking software often work with three scenarios: Standby, Pre-comfort, and Comfort. If the room is not booked, the control system lowers the temperature to 16°C, for example. If the guest is expected shortly, the room is preheated to about 19°C. When guests check in, the control switches to a comfortable 21°C. As the customers are king, they can set their preferred temperature in the room themselves using the RBW/RPW control unit. If they like it hot, the setpoint can be increased to 25°C, for example. As soon as the guest departs, the hotel operator in the control room can reset the temperature to the original setting. Of course, that also applies to all other guests and rooms. If the room control is linked to the booking system, it will even work automatically. That not only saves energy costs. Service personnel do not have to go into every room and turn the heating down manually.

Many automated rooms are used only at certain regular times – offices or classrooms, for example. An individual time program ensures that the heating in the room comes on only when it is occupied. In conjunction with building automation, time programs can also be set centrally for the rooms in entire departments or floors. A classic is temperature reductions at night or during vacations. This saves energy costs and protects the environment – automatically.

No one has to fiddle around with a screwdriver to put an RBW/RPW room control unit into operation: just hold a magnet to the service pin. The unit is then active.

With their timeless, understated design, RBW/RPW room control units fit discreetly into any room. All models have simple design lines. Clear controls and pictographs make the basic functions easy to understand. In the flush-mounted versions, the wall structure is particularly flat – barely 16 millimeters in depth.

You can assign the buttons on RBW control units individually. We also provide the labels so that every room user knows which function is assigned to which button. The labels for standard functions like light or blinds are already preprinted and only have to be inserted under the strong Plexiglas cover on the button in question. For individual functions or scenarios such as “Presentation”, you can print out the labels yourself in the same design – we supply the template files.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/8/csm_KuP_Enrico_Jagoschinski_8c12aed272.jpg)