Is it possible to turn a rehabilitation clinic’s 30-year-old heating and ventilation system into a showpiece for climate protection and major energy savings – at minimal expense, in a short space of time and all during ongoing operation? “Yes, it is – and we have the proof!” says Michael Schlüter from Kieback&Peter’s Münster branch. With their combined expertise and the smart CO₂ Reduction Roadmap from Kieback&Peter, the sales engineer and his team have achieved a real sensation in the Lindenplatz and Quellenhof rehabilitation centers: “The new control system has permanently reduced the gas consumption of the existing systems by around 30 percent – without major investment and while maintaining the same level of comfort for patients and employees. So we have significantly exceeded our targets.” But how did Kieback&Peter manage to achieve this?

Around 30 percent lower energy consumption – thanks to smart automation

The Lindenplatz and Quellenhof clinics in Bad Sassendorf, Germany belong to the Westfälisches Gesundheitszentrum health center and provide a modern orthopedic rehabilitation facility. The center offers inpatients and outpatients innovative therapies with a high quality of treatment. A heating and ventilation system regulated by a Kieback&Peter control system has ensured pleasant room temperatures and good air quality throughout the entire building complex since 1993.

“Thirty years ago, this was a high-tech system. But by 2021, the technology had become more like a vintage car – it may still run fine but uses far too much energy by today’s standards,” explains Schlüter, describing the situation before the modernization. Since Kieback&Peter had been maintaining the system since its construction, the efficiency experts were aware of the unnecessarily high energy usage and took action: “I suggested to our customers at the clinic that we could use the CO₂ Reduction Roadmap to massively reduce the immense energy costs and thus also the carbon footprint in line with the Paris Agreement – without major investment costs. A short time later, I was able to present our concept in detail, and it quickly became clear to everyone that this was the ideal solution.” The CO₂ Reduction Roadmap was designed for existing buildings that require refurbishment to make them more energy efficient in order to meet the Paris climate protection targets. The agreement stipulates that all buildings in the European Union must be carbon neutral by 2050.

Roadmap to the CO₂ target – climate-friendly and subsidized by the federal government

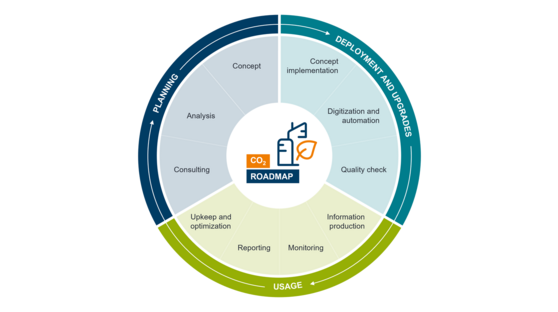

“Three steps, three months, one climate goal: to achieve net zero. This is how our CO₂ Reduction Roadmap works in a nutshell. It is suitable for all types of buildings, complies with all relevant standards and can be standardized – it’s truly ingenious,” says Michael Schlüter, proudly adding: “At the Lindenplatz clinic, my team and I proved that the roadmap not only quickly achieves the intended goal, but even exceeds the promised savings effects by quite some margin.”

The three steps in Kieback&Peter’s CO₂ Reduction Roadmap are as follows: 1. analysis of the status quo, 2. technical concept and 3. CO₂ reduction. At the Lindenplatz clinic, the initial analysis was therefore followed by a sophisticated optimization plan for the existing technology, including precise profitability calculations and concrete savings targets. Sales engineer Michael Schlüter, project manager Jürgen Nöhmke and sales engineers Jens Nicolaus and Tobias Götte planned to bring the old system technology up to date with modern, demand-driven automation and thus maximize its operating efficiency. Their calculations showed that the investment would pay for itself within just a few years – especially with the 25 percent subsidy through the federal funding for efficient buildings (BEG) program.

Three steps, three months, one climate target: net zero

Within three months, the CO₂ reduction roadmap can already provide stakeholders with initial, lasting benefits through CO₂ reduction and energy savings. The experts develop and implement a tailor-made solution package for each individual property, based on up to nine standardized modules.

This includes everything that is required in each case - from expert advice, measurement, control and regulation technology from software and hardware “Made in Germany” to data-based services such as cloud solutions for optimal and sustainable building operation.

On-demand rather than continuous operation– for optimum efficiency

How can the energy consumption of a large rehabilitation clinic be significantly reduced without fundamentally renewing the heating and ventilation technology? Michael Schlüter tells us: “We simply gave the existing heating and ventilation modern operating rules – and now everything is demand-driven. With the old technology, the two gas boilers were in continuous operation throughout the year. The new automation system now determines the actual heating requirement and only starts up the boilers when heat is needed.” The main part of the modernization consisted of bringing the old automation system up to the latest state of the art.

In particular, the type DDC100 controllers dating back to 1993 were replaced with modern controllers: “By today’s standards, they are dinosaurs, although they were state of the art at the time. They cannot be programmed and can only implement standard rules. To ensure highly efficient operation, modern automation stations are a necessity.” The team replaced the computers with powerful DDC4040 controllers from Kieback&Peter: They make it possible to implement comprehensive programs and control the building technology down to the smallest detail. This includes boilers, pumps, fans, control cabinets and sensors.

Minimized carbon footprint – thanks to continuous adjustment

Thanks to the new automation system, the existing ventilation hardware now works with sophisticated programming according to the principle “as much as necessary, as little as possible.” The automation professional explains how this works: “As is the case with most old ventilation systems, the fans ran continuously at level 2. This meant they transported a constant amount of air without interruption – regardless of whether a room was fully occupied and there was a high demand for fresh air or whether it was completely unused and they did not need to be running.”

For the new ventilation control system, regional specialist trades installed carbon sensors according to the team’s plans. Based on the values measured by these sensors, the control system can start the fans whenever fresh air is actually needed. “The demand-based ventilation control not only ensures the fans use considerably less energy; in many areas, the air quality and thus comfort has also improved – for example in the dining room at lunchtime.” As was the case with the heating system, no new hardware had to be installed for the ventilation system – the only new components are the controllers and the carbon sensors.

Lower costs, happy customers – and the environment will be equally grateful

What conclusions does Kieback&Peter draw from its efforts to achieve energy savings in the Lindenplatz/Quellenhof clinic using the CO₂ Reduction Roadmap? “We succeeded in considerably reducing the clinic’s energy consumption within a few months and with little investment. That is the most important thing, as it means we fulfilled our promise. 30 percent lower energy consumption is a much bigger reduction than is normally possible. This shows that our CO₂ Reduction Roadmap works,” says a delighted Michael Schlüter, adding: “Our clients also praised us for the smooth implementation.” The other major benefit is that the environment will also be very grateful as the new automation system significantly reduces carbon emissions.

![[Translate to Englisch:] Elbdeck [Translate to Englisch:] Elbdeck Hamburg](/fileadmin/_processed_/9/b/csm_11_Deutschland_Hamburg_Elbdeck_3011f21c3c.jpg)

![[Translate to Englisch:] Qu4drans Paris [Translate to Englisch:] Qu4drans Paris](/fileadmin/_processed_/f/2/csm_Qu4drans_e315f9ef8d.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/3/d/csm_L_T_Sporthaus_Osnabrueck_Indoor_kieback-peter_d47dda6a97.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/6/f/csm_flevo-krankenhaus-aussenansicht-kieback-peter_7f540b4b4f.jpg)